Pvc: Understanding Its Meaning & Uses

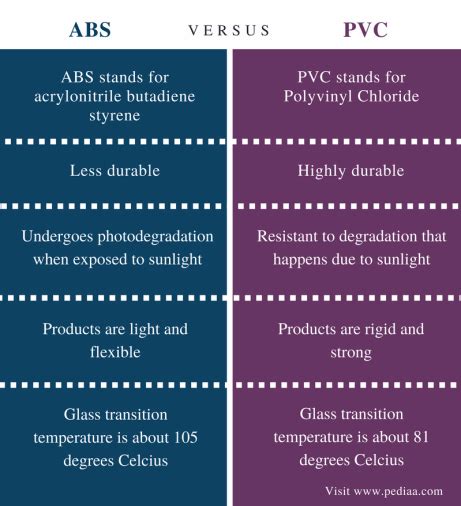

Polyvinyl Chloride, commonly abbreviated as PVC, is a versatile and widely used synthetic plastic polymer. Its exceptional durability, resistance to corrosion, and affordability have made it an essential material in various industries, including construction, healthcare, and consumer goods. In this comprehensive overview, we will delve into the meaning, properties, and uses of PVC, exploring its significance and applications in modern society.

Historical Background of PVC

The discovery of PVC dates back to 1872 when German chemist Eugen Baumann first synthesized the polymer. However, it wasn’t until the early 20th century that PVC began to be commercially produced, with the first PVC factory opening in the United States in 1926. Since then, PVC has undergone significant developments, leading to the creation of various types of PVC with different properties and applications.

Properties of PVC

PVC is known for its unique combination of properties, which make it a preferred choice for a wide range of applications:

- Durability and Resistance: PVC exhibits high resistance to chemicals, abrasion, and impact, ensuring its durability and longevity in various environments.

- Thermal and Electrical Insulation: PVC acts as a good insulator against heat and electricity, making it suitable for electrical wiring and thermal insulation applications.

- Low Cost: Compared to other polymers, PVC is relatively inexpensive to produce, contributing to its widespread adoption.

- Flexibility and Rigidness: Depending on the formulation, PVC can be made flexible or rigid, allowing for its use in a variety of products, from pipes and fittings to vinyl records and credit cards.

- Water Resistance: PVC’s resistance to water and moisture makes it ideal for use in plumbing, drainage systems, and outdoor applications.

Uses of PVC

The versatility of PVC has led to its use in numerous industries and applications:

- Construction Industry: PVC is extensively used in the construction sector for producing pipes, fittings, and profiles due to its durability and resistance to water and chemicals.

- Electrical Industry: The insulating properties of PVC make it a crucial material for electrical wiring and cables.

- Medical Applications: PVC’s flexibility, biocompatibility, and resistance to chemicals have led to its use in medical devices, such as tubing, IV bags, and medical gloves.

- Consumer Goods: PVC is used in a wide array of consumer products, including vinyl records, credit cards, and clothing.

- Signage and Advertising: The rigid form of PVC is often used for making signs and displays due to its durability and ease of fabrication.

Environmental and Health Concerns

Despite its many benefits, PVC has raised several environmental and health concerns. The production of PVC involves the use of vinyl chloride monomers, which are known carcinogens. Additionally, when PVC is incinerated, it can release dioxins, substances that are harmful to human health and the environment. There has been a growing movement towards finding more sustainable and environmentally friendly alternatives to PVC, as well as developing safer methods for its production and disposal.

Safety Precautions and Handling

Handling PVC requires certain precautions to minimize risks:

- Use Protective Gear: When working with PVC, it is essential to wear protective gear, including gloves, goggles, and a mask, to prevent exposure to potentially harmful chemicals.

- Follow Manufacturing Guidelines: Adhering to the recommended manufacturing processes can help reduce the environmental impact and health risks associated with PVC production.

- Proper Disposal: Ensuring that PVC products are disposed of properly, through recycling or appropriate waste management facilities, can help mitigate environmental hazards.

Future of PVC

As the world moves towards more sustainable practices, the future of PVC is likely to involve significant changes. Researchers are exploring alternatives to PVC that offer similar benefits without the environmental and health drawbacks. Additionally, efforts to improve recycling technologies and implement more sustainable production methods are underway. The development of bio-based PVC and the use of recycled PVC materials are among the strategies being considered to reduce the environmental footprint of PVC.

Conclusion

PVC has been a cornerstone of modern industry due to its versatility, durability, and cost-effectiveness. However, its production and disposal have raised significant environmental and health concerns. As society moves towards more sustainable practices, it is crucial to address these challenges through innovative production methods, improved recycling technologies, and the development of more environmentally friendly alternatives. By understanding the properties, uses, and impacts of PVC, we can work towards a future where its benefits are realized while minimizing its negative consequences.

What are the primary uses of PVC in construction?

+PVC is primarily used in the construction industry for producing pipes, fittings, and profiles due to its durability and resistance to water and chemicals. It is ideal for plumbing, drainage systems, and other applications where moisture resistance is crucial.

Is PVC safe for medical use?

+PVC’s flexibility, biocompatibility, and resistance to chemicals have led to its use in medical devices. However, concerns about the potential release of harmful substances during production and disposal have prompted the development of safer alternatives and more stringent manufacturing standards.

How can PVC be recycled?

+PVC recycling involves collecting PVC products, sorting them based on their type, and then processing them into raw materials that can be used to manufacture new products. Closed-loop recycling, where PVC products are recycled into the same type of product, is considered the most effective method for minimizing waste and reducing the demand for virgin PVC.